In the rapidly evolving cannabis industry, traceability systems are typically viewed through the lens of compliance. Whether it’s meeting state-mandated seed-to-sale requirements or ensuring secure transport of regulated products, traceability data often seems like a regulatory burden. But savvy operators are flipping the script. When used strategically, this data can provide powerful operational insights—unlocking efficiencies and boosting profitability in surprising ways. Here are five unexpected benefits of cannabis traceability data that go beyond compliance.

1. Smarter Labor Forecasting

Cannabis businesses, especially vertically integrated ones, experience fluctuating demands across cultivation, processing, and retail. Traceability data can pinpoint peak activity times—harvest cycles, popular shopping days, or extraction bottlenecks—and help operators forecast labor needs more accurately. For example, analyzing historical harvest-to-sale timelines can inform when to hire more trimmers or staff more budtenders. By predicting these labor demands, businesses can reduce overtime, avoid understaffing, and improve overall workforce efficiency.

2. Decoding Customer Behavior Trends

Seed-to-sale systems track every touchpoint—from the strain and form factor a customer buys, to the frequency and size of purchases. With this data, operators can segment customers by buying habits. Is a particular group gravitating toward pre-rolls before the weekend? Are medical patients stocking up on tinctures monthly? These trends are goldmines for targeted marketing campaigns and product assortment decisions. Retailers can customize promotions and bundle offers to fit consumer preferences with pinpoint accuracy, ultimately improving customer satisfaction and lifetime value.

3. Regional Sales Pattern Optimization

Every market has its own personality. What flies off the shelves in Miami might sit untouched in Flagstaff. Traceability data offers operators a way to study these regional nuances in real time. By mapping product performance across multiple dispensaries or delivery zones, businesses can better manage inventory, reduce stockouts, and avoid overproduction. These insights also guide regional pricing strategies and allow cultivators to plan strain outputs that align with regional demand, enhancing margins across the board.

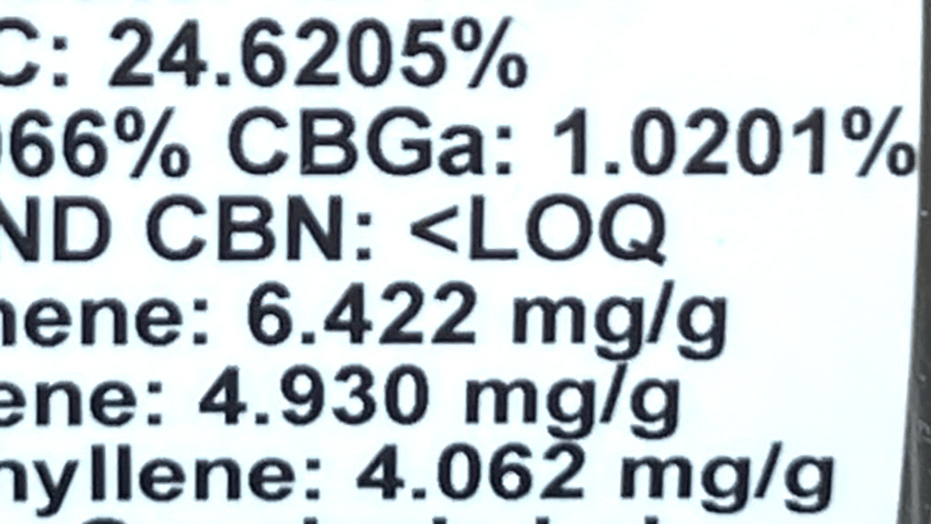

4. Enhanced COA (Certificate of Analysis) Utilization

COAs are often treated as check-the-box documents required for compliance, but they can be leveraged to elevate product quality and consumer trust. Traceability platforms that integrate COA data allow operators to analyze cannabinoid and terpene profiles across batches and link them to product performance or consumer feedback. This feedback loop can influence cultivation methods, refine product formulations, and support educational content for customers. Imagine promoting a vape cartridge with “verified myrcene levels for ultimate relaxation”—sourced directly from COA-backed traceability data.

5. Cross-Functional Insights for Product Development

Perhaps the most powerful but underutilized benefit of traceability data is how it enables cross-functional decision-making. Sales trends, COA data, customer behavior, and production timelines can be synthesized to inform new product development. For example, if data shows that edibles with high-CBD ratios are performing well in Florida’s senior market, a processor can respond by developing more SKUs in that category. These insights reduce guesswork and increase product-market fit.

Final Thought

In an industry where margins are tightening and regulations are intensifying, cannabis operators can’t afford to view traceability data as just a compliance checkbox. Used wisely, this data becomes a competitive advantage—powering smarter labor management, better customer targeting, region-specific strategies, and more intentional product development. The cannabis businesses that embrace these unexpected insights are the ones poised to scale and thrive in an increasingly data-driven market.